Overview

This is a smart scheduling system designed for RL Auto Repair, a family-run shop in Rahway, NJ. The shop was experiencing workflow delays, underutilized lift stations, and missed opportunities for quick-turnaround jobs. As the lead designer and strategist, I created a solution to optimize how cars are scheduled into the space, ensuring that lift time, mechanic availability, and job size are all balanced to maximize daily efficiency and revenue.

The Challenge

At RL Auto Repair, jobs were scheduled manually without factoring in actual lift capacity or labor time. This often resulted in:

✦ Backlogs due to large jobs occupying space for hours

✦ Idle lifts when customers didn’t show up or jobs ran shorter than expected

✦ Missed out on small jobs that could’ve filled open slots

✦ Manager overload, scheduling relied heavily on memory, paper, and calls

Research & Insights

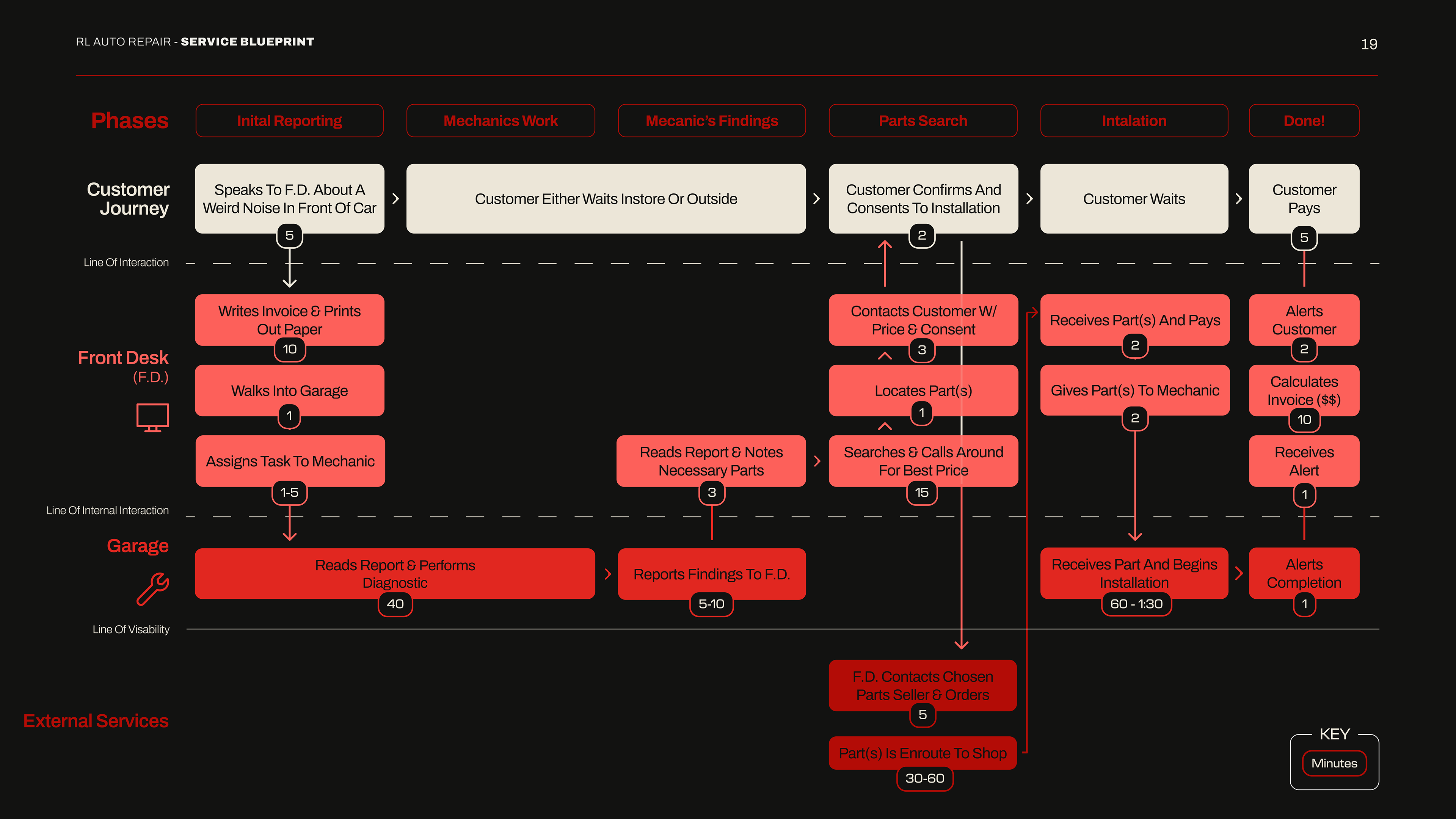

To uncover pain points, I interviewed the shop owner, assistant manager (myself), and mechanics. I also mapped out the service flow and tracked real-time job data. Some key findings:

✦ Technicians often finished jobs earlier than expected, but couldn’t take on new ones

✦ Customers wanted more clarity about drop-off times, especially for quick services

✦ The shop made less money on days with fewer small jobs, even when fully booked

✦ The current “first come, first served” system was costing both time and revenue

Service & System Design

I redesigned the scheduling flow from the ground up, aligning it with how jobs actually move through the shop. This included:

✦ Smart job slotting based on estimated labor time and bay availability

✦ A responsive system that re-adjusts the schedule in real-time

✦ Visual scheduling tied to lift stations to avoid physical bottlenecks

✦ Ways for customers to select pick-up/drop-off methods and deposit.

Testing & Feedback

I tested the system using a Concierge MVP, manually simulating the smart scheduling logic over several weeks. By tracking job durations, lift availability, and mechanic capacity in real time, I was able to observe how the system would function without full development.

✦ Small jobs could be fit into open slots without disrupting larger repairs

✦ Mechanics appreciated clearer, real-time visibility into their workflow

✦ The managers spent less time adjusting schedules manually and focused elsewhere

Presentation Media (13/47)

Interview Title Card

Focus Group - Goal

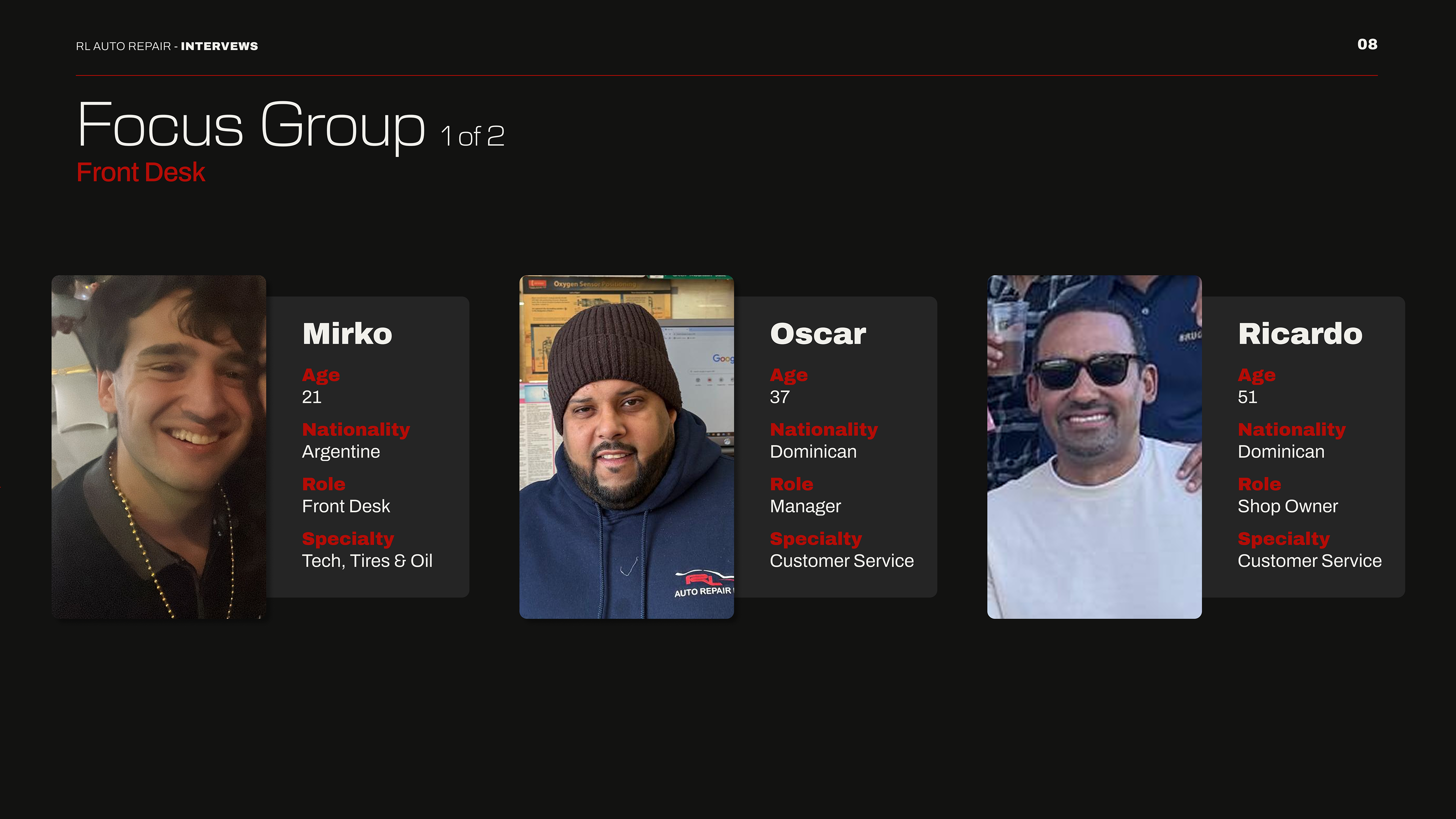

Focus Group 1

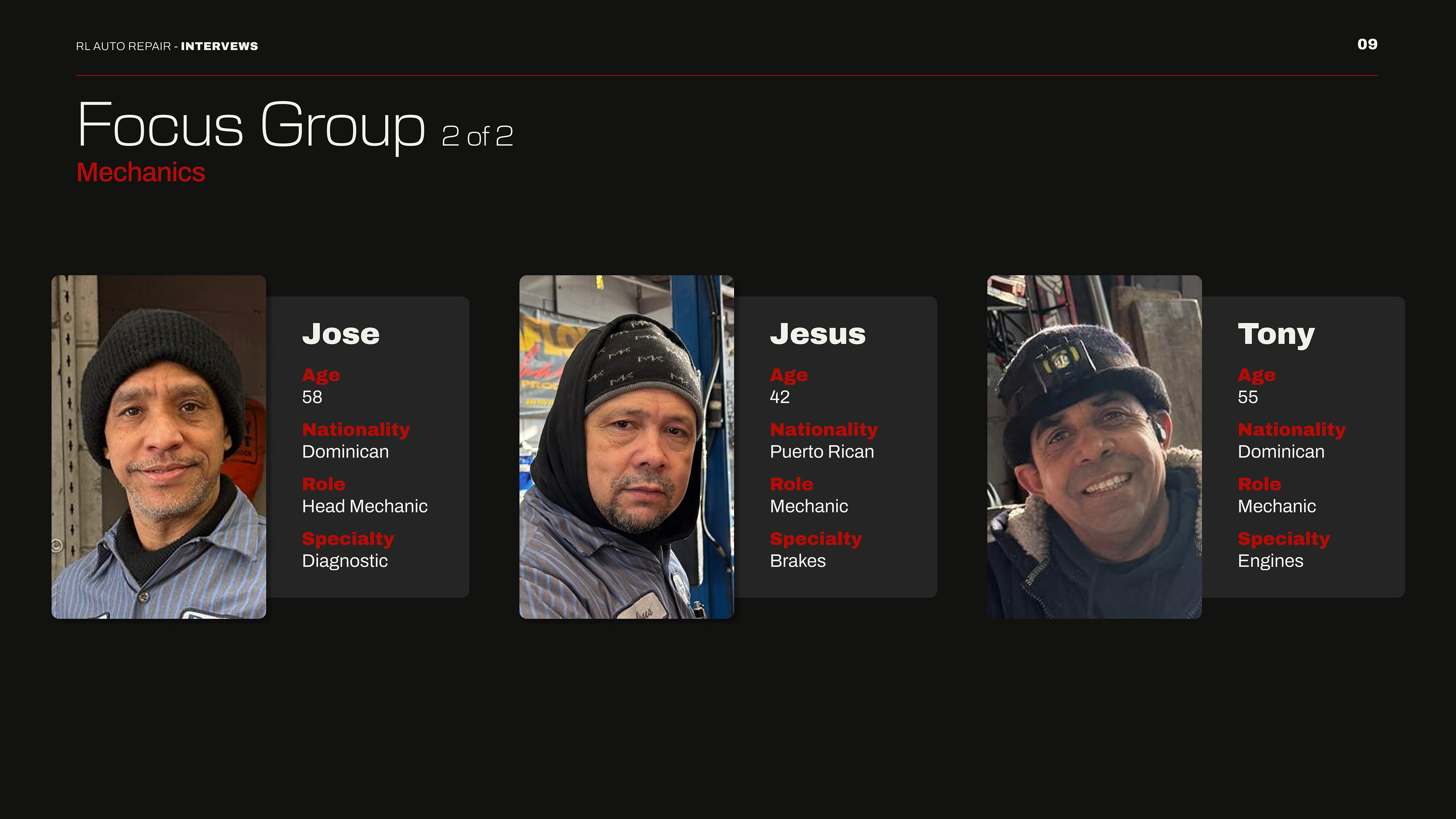

Focus Group 2

Service Blueprint Title Card

Service Blueprint - Goal

Service Blueprint

Quarterly Income Analysis Title Card

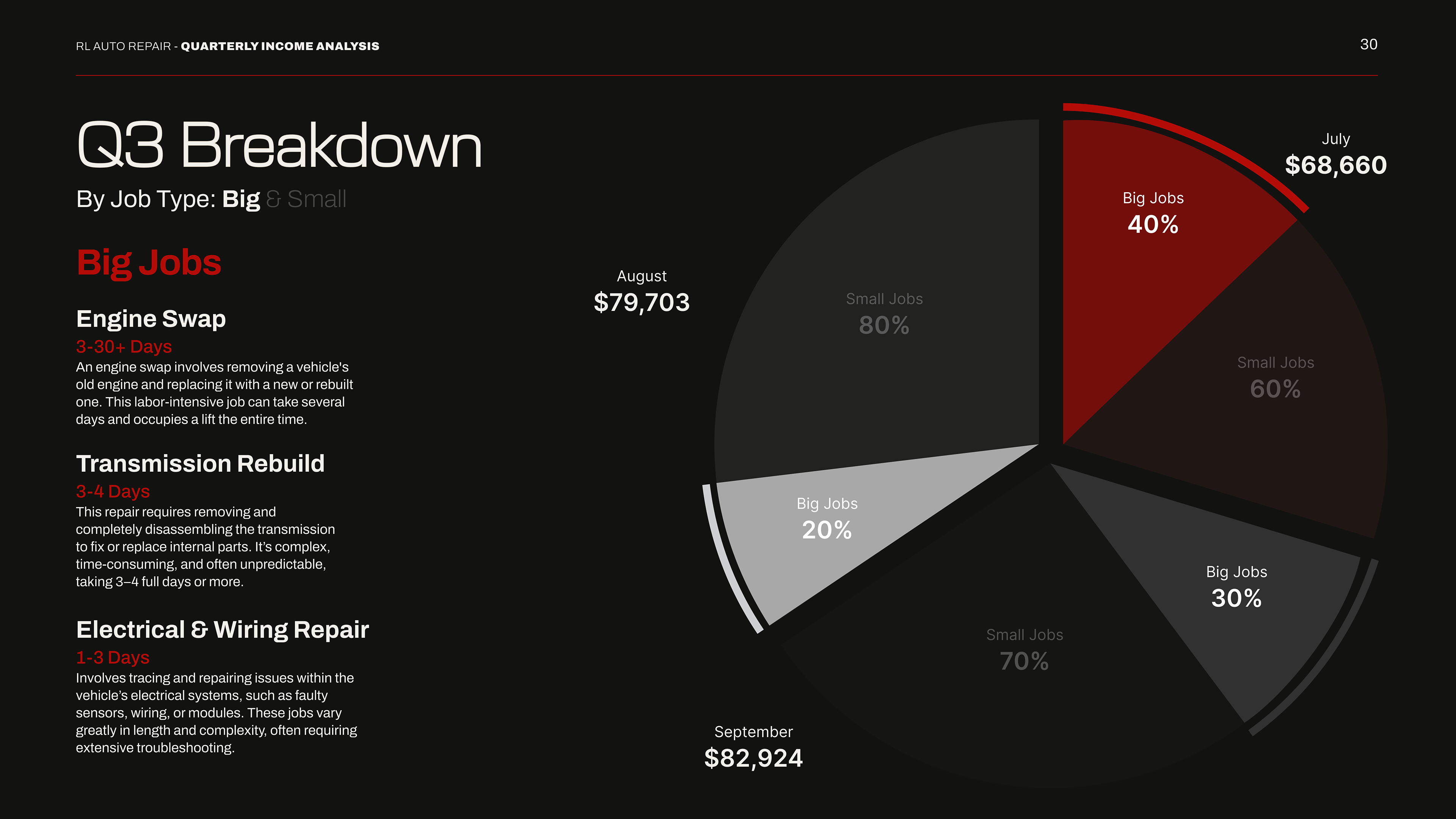

3rd Quarter Income Breakdown (Big Jobs)

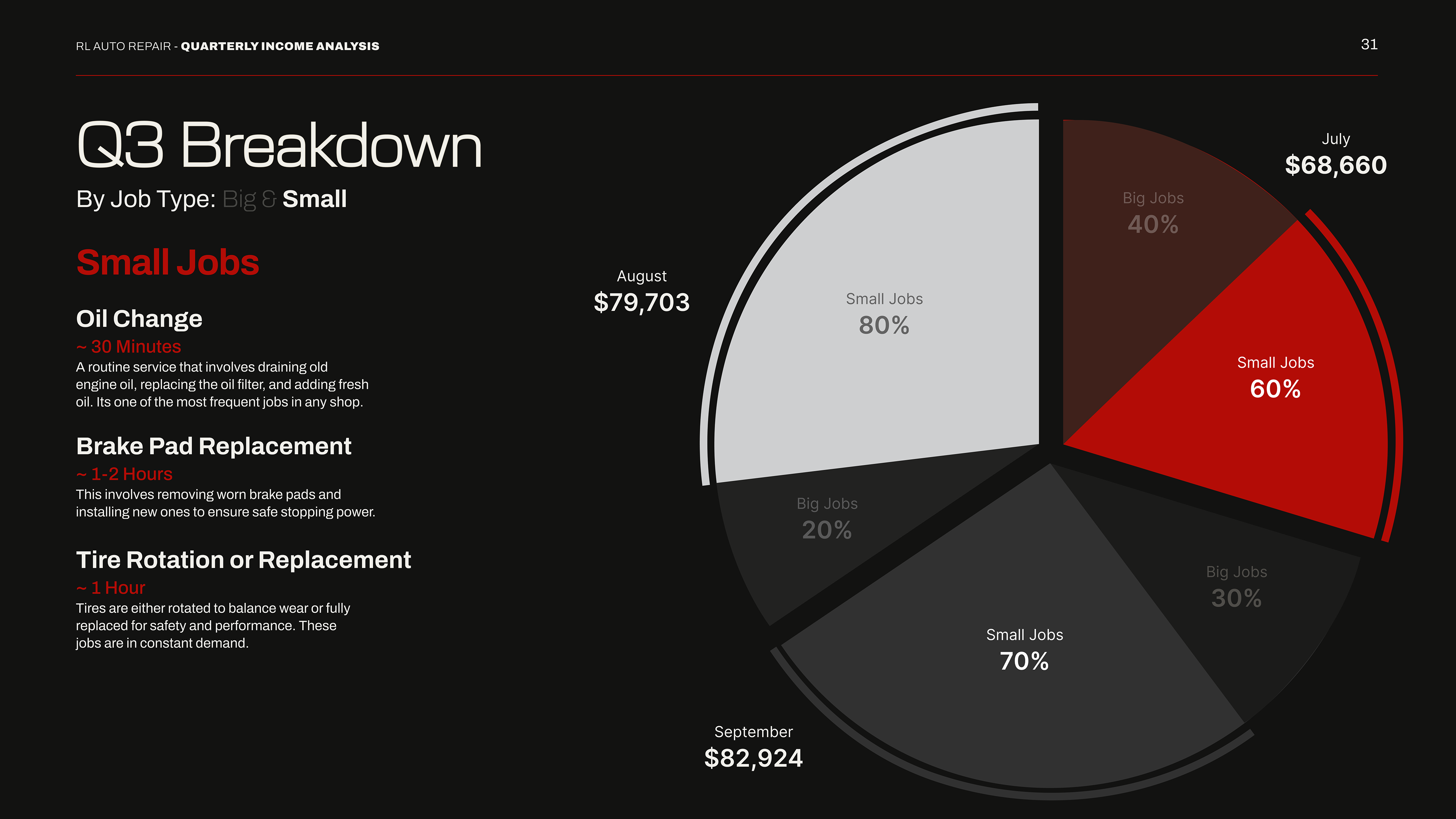

3rd Quarter Income Breakdown (Small Jobs)

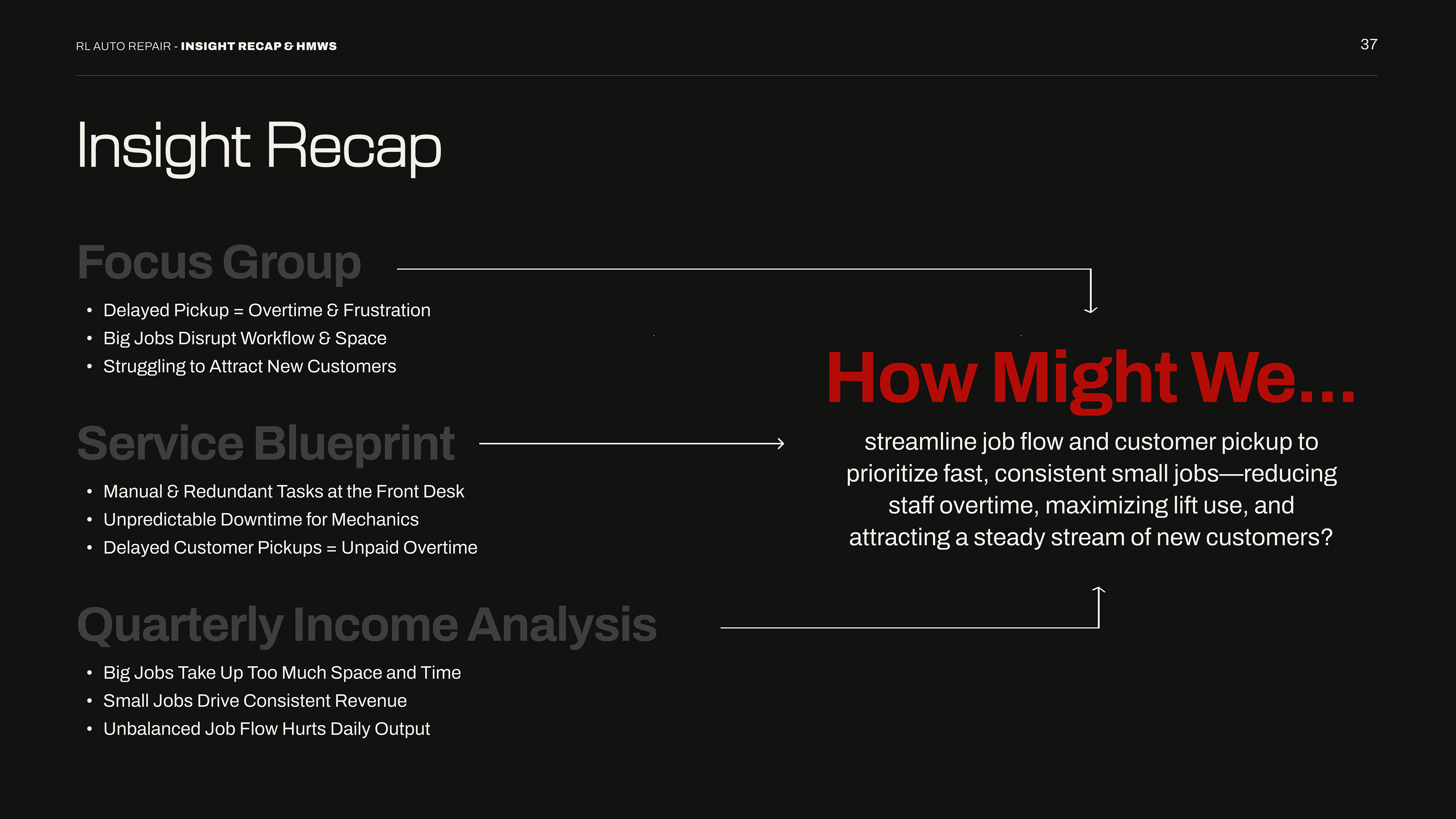

Insight Recap & How Might We...

Concierge MVP/UXM Walkthrough with Oscar and Mirko

Promo Video